SUSTAINABLE FACTORIES | SUSTAINABLE BUILDINGS

with

POWER SMART COAT (PSC) ENERGY SAVING and ENVIRONMENTAL PROTECTION

Heat flow is an inevitable consequence of contact between objects of different temperature. Thermal insulation provides a shield in which thermal conduction is reduced or thermal radiation is reflected.

POWER SMART COAT is based on a Swiss patented technology that utilizes the properties of closed porous spherical fillers MICROSPHERES. The properties of the MICROSPHERES allow the coat to effectively minimize heat transfer between surfaces with a thin layer of application.

ABOUT POWER SMART COAT (PSC-250T)

POWER SMART COAT is based on a Swiss patented technology that utilizes the properties of closed porous spherical fillers MICROSPHERES. The properties of the MICROSPHERES allow the coat to effectively minimize heat transfer between surfaces with a thin layer of application.

POWER SMART COAT also provides other performance benefits:

- Ability to withstand temperatures from -60 to 200 degrees Celsius

- Efficient Thermal Insulation (Up to 91% infrared radiation reflectance)

- Corrosion Prevention

- Moisture resistance (Water proof)

- Surface Temperature Reduction

- Chemical Resistance

- Lead Encapsulation

- Non-Toxic

- Mold Resistance

- Durability in Extreme environments

- Lengthening Operational Lifespan of applied items

- For both indoor and outdoor surface applications

HOW CAN POWER SMART COAT (PSC-250T) WORK FOR YOU

HOW POWER SMART COAT (PSC-250T) WORKS

- With each applied layer of POWER SMART COAT application a vacuumed structure is form

on the applied surface.

on the applied surface. - This layer which is a solid waterproof film (60-80 microns) consist of microspheres

- The middle and top portion of this layer are softer and elastic, comprising of primarily closed air spheres

- Upon evaporation of the liquid content, the resulting effect is a uniform distribution of the microspheres across the applied surface

- This ensures maximum adhesive and thermal insulation effectiveness of the applied surface

- Thickness of application coat is between 2- 3mm (depending on type of surface)

- The coated layer has up to 91% infrared radiation reflective capabilities

- Universal Application allowing for application on various type of surfaces

- Convenient Application: Manual and mechanical methods

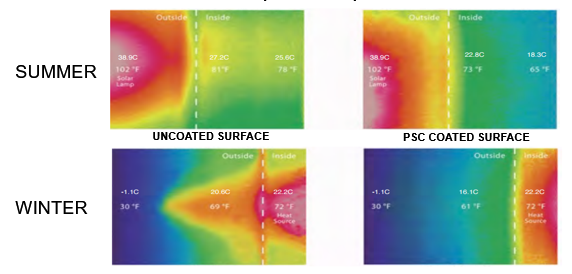

POWER SMART COAT (PSC-250T) – THERMAL IMAGING

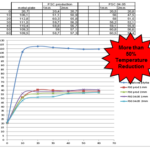

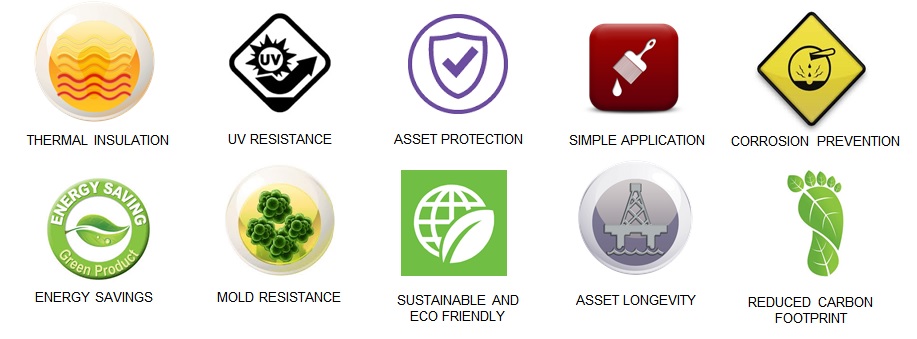

POWER SMART COAT (PSC-250T) – REAL TIME TEMPERATURE REDUCTION

POWER SMART COAT (PSC-250T) – APPLICATIONS

POWER SMART COAT (PSC-250T) – PROJECTS GALLERY

POWER SMART COAT (PSC-250T) – CASE STUDIES

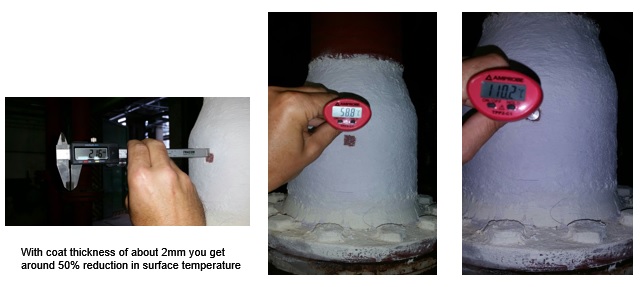

POWER SMART COAT (PSC-250T) – COMPARISON CHARTS

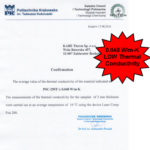

POWER SMART COAT (PSC-250T) – LAB TESTING DATA