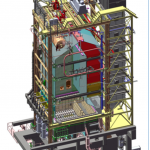

Fluidized bed boilers with temperature-controlled fluidized bed

TENZA, a.s. offers deliveries of steam boilers employing unique fluidized bed technology. It combines the advantages of stationary (bubbling) and circulating fluidized beds. This type of boilers covers the steam output range from 30 to 100 tph and is capable of burning not only coal but also coal in combination with a considerable proportion of biomass.

It is a water-tube, self-supporting, single-drum boiler with natural circulation. Thanks to its compact design, only small area is necessary for this type of boiler and therefore the space in a boiler room can be used efficiently.

Wide smooth output regulation from nominal maximum to mere 30% of nominal output is possible thanks to a brand new design of the bed which is protected by a patent. The fluidized bed with horizontal circulation and controlled temperature regulation ensures perfect mixing of fuel in the fluidized bed section. The unique combustion chamber design contains two fluidized beds: the main bed where combustion takes place and the heat transfer bed where heat is taken from. This division is important for individual output ranges of the boiler. The fluidizing material circulates from the main to the heat recovery bed with a cooler. The circulation flow is extremely effective in increasing the combustion efficiency and improving the desulphurization.

The qualities of the combustion chamber include:

- slight pressure loss in the fluidized bed,

- thorough horizontal mixing of fuel in the bed,

- considerable transmission of heat to the tubes dipped in the heat transfer bed as a heat exchanger,

- minimal erosion of the heat exchanger thanks to low fluidizing speeds,

- constant conditions under low outputs,

- ash recirculation for higher combustion efficiency.

The low-temperature fluidized combustion makes partial desulphurization possible in the fluidized bed by using additives and also keeps nitrogen oxide values low. The technology applied meets the requirements for low-emission operation thanks to temperature-controlled fluidized bed and adding limestone directly to the combustion equipment.

Gallery

Want to know more? Contact us!