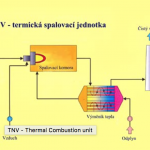

Thermal Combustion Equipment – TNV

Thermal combustion equipment guarantees – thanks to its advanced technical solutions – fulfilment of the most demanding emission limits with efficiency exceeding 99,9 %. An important characteristic point is high universality of use. Under temperatures usually reaching 700 – 800°C the organic pollutants oxidise to2O and CO2. Then, the oxidation temperature may reach up 1200°C for liquidation of pollutants with higher demands on temperature.

Characteristics of thermal combustion systems:

- High cleaning efficiency (> 99, 9%)

- High utility efficiency in operation process

- Efficient use of waste heat

- Above-standard service life

- Automatic operation

- Simple servicing and maintenance

- Compact construction form

- Special version for degases with pre-set zone of explosion risk “0” or “1”

Parameters:

- Compact version with integrated heat exchanger

- Version with combustion chamber and additional exchangers

- Combustion chamber with ceramic, heat-resistant filling

- Possibility of using various sources of additional power

- Possible combination with various dust filters, desulphurisation, deNOx, etc.

- Non-stop operation

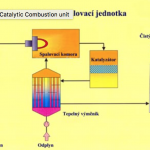

Catalytic Combustion Equipment – KNV

We supply catalytic combustion equipmentin compact or modular version, in the variants of a honeycomb catalytic converter and pellet catalytic converter. Our experts assess the given situation on the basis of pilot tests and they set optimal type of the catalytic converter and operation conditions.

Due to many risk factors of catalytic units, there are currently preferentially supplied the thermal combustion systems. Supplies and performances in the sphere of catalytic combustion move mainly towards overhauls of own units, as well as foreign units in the territory of the Czech Republic.

Selection parameters:

- Compact and modular version

- Honeycomb catalytic converters and pellet catalytic converters

- Auto-thermal operation ad from 1-4 g/Nm3

- Heating with liquid gas fuels or electric power

- Regenerative or recuperation pre-heating of degas, use of waste heat

Catalytic combustion equipment are characterised with:

- Low consumption of additional fuel

- High regulation abilities in relation to quantity, temperature and contents of combustible substances in degas

- Stable and excellent oxidation of pollutants to the full regulation extent

- Automatic staff-free operation

Combustion systems with regeneration of heat contained in outlet cleaned degas. Heat efficiency up to 95% brings low consumption of supporting fuel with large volumes of exhausted air.

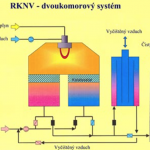

Description of RTNV a RKNV

The ceramic bed accumulating heat under high temperatures in the combustion chamber guarantees long service life.

The combination of a catalytic converter with pre-heating of the inlet degas creates a really compact equipment working in auto-thermal operation just from low concentrations of organic substances – this is suitable in cases when it is not possible for gas supporting fuel to be used and under elimination of risk factors in case of degas.

As from 2003, new ceramic filling with low pressure resistance has been used, which brings significant savings in electric power consumption.

Combustion systems with heat regeneration are characterised as follows:

- Low consumption of additional power

- High regulation range of the unit (1:6)

- Stable and excellent combustion in the whole regulation range

- Automatic control system and staff-free operation

- Long-term service life and non-demanding maintenance

Parameters:

- Thermal or catalytic version

- Use of waste gas with efficiency rate up to 95%

- Auto-thermal operation as from 1,5 g/Nm3 hydrocarbons

- Input concentration of pollutants up to 5g/Nm3

- Short-term peaks up to 8g/Nm3

Cupolas

The most advantageous solution means that the equipment for cleaning of offgas from cupolas is included directly into the mineral wool production line. Together with trapping the dust elements and consequent final burning of carbon monoxide, it is possible for the combustion power to be used for process air pre-heating, as the temperature of 650°C or more can arrange significant heat savings in cupolasduring melting.

Equipment optimisation, improved control and integrated visualisation allow its application even under significantly hardened conditions. Due to these reasons, the mineral wool producers prefer our equipment.

Cleaning equipment is characterised as follows:

- Low fuel consumption

- High regulation abilities in relation to the flow quantity, temperature and contents of combustible substances

- Stable and excellent combustion in the whole regulation range

- High efficiency of dust removal

- Automatic and staff-free operation

- Long-term service life and simple servicing

Parameters:

- High input concentration in offgas

- CO contents in cleaned offgas below 100mg/Nm3

- Dust concentration in cleaned offgas below 20mg/Nm3

- Pre-heating of air for the furnace up to 700 °C

- Integration of additional equipment for offgas cooling with water, DeSOx and secondary use of waste heat

Rotary concentrator

Rotary concentrator is used for production technologies combining high levels of exhaust gas and low concentration of VOC. Rotary concentrator provides concentration of VOC in 1:10 (1:15) ratio for the follow-up disposal using catalytic ot thermal technologies. Rotary concentrator is most commonly used in the areas of painting lines, plastics production, paper industry etc.

The rotary concentrator is based on zeolite filling set in the round shape constantly rotating and divided in several sections: process (300-310°), cooling (20-30°) and desorption (25-30°). Organic substances are caught on the surface thanks to intermolecular power, no chemical bond is operating here. Synthetic zeolites are more fire safe compared to active coal, particularly when using ketones as solvents.

1. Adsorpton phase:

Off-gas from the production (with the environs temperature around 25°C) comes through a solid substance filter first and then through the process sector of the rotary adsorber. Organic substances contained in the off-gas are adsorbed on the zeolite surface under the consistence of 50 mg/Nm3 TOC. Cleaned off-gas leaves through an adjacent ventilation system directly into the atmosphere.

2. Desorption phase:

Desorption air (gained by desorption ventilator) consists of detached part of the process off-gas (ca 1/10). The air is driven through the cooling sector of the rotary wheel, then is heated to the temperature of 120 – 180°C in the preheating exchanger and displaces organic pollutants from the zeolite filling on the way through the desorption sector of the rotary wheel. Concentration is ca 10 times increased compared to the original off-gas. The outgoing desorption air flow (ca 80 – 110°C) is then bound to be cleaned using thermal or catalytic methods.

Advantages of the rotary concentrator:

- Simplicity and sefety of its use

- Low operating and service costs

- Wide range of sizes suitable for any operation size (basic line covers air volume from 12.000 Nm3/h to 100.000 Nm3/h)

- Long life of adsorption material

- Automatic operation

Adsorption

Depending on specific circumstances, the adsorption – as a method of pollutants liquidation – may be a good alternative of the oxidation methods. Taking into consideration the character of pollution, we offer:

- Sorption in fixed bed

- De-sorption in compact version with sorption

- Continuous sorption and de-sorption with rotary adsorber

- External de-sorption on own or leased equipment.

We will recommend the most suitable procedure, taking into consideration the operation and investment costs.

Characteristics of adsorption systems:

- Minimal efficiency is 75% for odour substances and 90% for standard solvents.

- Low purchase costs and wide spectrum of use

- Selection of adsorber type exactly made to measure of the environment and operation conditions

- For staff-free and permanent operation

- Chemical sorption – adsorption on chemically treated active coal for trapping various odour substances.

The adsorption equipment works on the basis of two principles:

- On the principle of reversible trapping of gaseous organic substances (standard solvents) on active surface. When reaching the level below the minimal efficiency rate, the exhausted filling is replaced with a new one or re-generation is performed.

- On the principle of non-reversible trapping of gaseous substances on active surface with the accompanying chemical reaction (chemical sorption). When reaching the level below the minimal efficiency rate, the exhausted filling is replaced with a new one. A specialised company performs liquidation of used fillings. Re-generation is impossible.

Gallery

Want to know more? Download product leaflet here or send us an email.