Vertical mills

Vertical (hammer) mill made by our company is the machine for milling of cereals determined. Material is milled by beaters in a high speed rotated as well as by friction between cover of sieve and raw materials.The machine is determined for montage in technologic plants, where is made the fodder mixtures for animals. There are such equipment as a silo for raw material and silo for milled material, also conveyers and the machines for processing of loose materials, in these plants. The mill is possible to use also for milling of bones in rendering plants, for milling of wooden wastes in wooden industry and some lumpy raw materials in various industrial plants. The machine is designed for grinding the following materials: cereals and grains, wood chips,sawdust, wood waste, straw, remnants of bricks, waste, raw lumpy, dried blood, spices, rendering plant and crushing bones, materials in the food industry (gingerbread, coconut etc.)

Vertical mills for wood waste

Vertical (hammer) mill made by our company is the machine for milling of cereals determined. Material is milled by beaters in a high speed rotated as well as by friction between cover of sieve and raw materials.The machine is determined for montage in technologic plants, where is made the fodder mixtures for animals. There are such equipment as a silo for raw material and silo for milled material, also conveyers and the machines for processing of loose materials, in these plants. The mill is possible to use also for milling of bones in rendering plants, for milling of wooden wastes in wooden industry and some lumpy raw materials in various industrial plants.

The machine is designed for grinding the following materials:

- chips (wet or dry)

- sawdust

- straw

- shaving

Turbo Mill (self-priming)

Turbo Mill (self-priming crushing mill) produced by our company is a machine designed for transport of processed materials via underpressure pipeline branch into the grinding space where the ground material is crushed by strikes of crushing bodies with high peripheral speed and discharged through screen shell via pressure pipeline branch into the container. The Machine is designed for integration into technological units (lines) consisting of material storage equipment (silos) designed for crushing, transport routes, and connected technological equipment for storage and processing of crushed materials. Accessories for suction and discharge transport routes will be combined according to the customer’s requirement.

Horizontal crushing mill

Horizontal crushing mill HM 22-37 produced by our company is a machine designed for shredding and crushing of materials with higher H2O (water) ratio. The material is crushed by strikes of crushing bodies with high peripheral speed and impacts on the internal surface of the enclosure. Material with granulation corresponding to the screen basket hole diameter falls through or is strained for further technological processing. The Machine is designed for integration into technological units (lines) consisting of storage equipment (silos) for materials designated for crushing, transport routes, and connected technological equipment for storage and processing of crushed materials.

Small feed mills

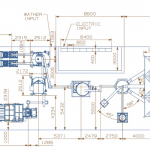

Small feed mill MVKS-V

Small feed mill MVKS-V is a system consisting of feeding pipe screw conveyor with a hopper and a bar screen, strain-gauge balance with hand control sliding gate, magnetic screen separator, vertical hammer mill, lower filling screw conveyor with a hopper for manual feeding of components, vertical mixer and inclined discharge conveyor with separate discharge and bagging spout.

Raw materials to be crushed are dosed in the strain-gauge balance placed above the hammer mill by the tube screw conveyor with the hopper and bar screen at the hopper inlet. After weighing of one charge, the raw material is freed from ferromagnetic impurities in its passage through the magnetic bar screen separator. Further the raw material is crushed by hammers in the vertical hammer mill, and calibrated through the screen to required granules. The screens can be easily replaced in off condition. The screen mesh size is selected depending on the kind of animals the feed is to be produced for.

The crushed material is further forced by the lower filling screw conveyor into the vertical mixer. On the filling screw conveyor there is a hopper with manual sliding gate for manual pouring of bagged components. The mixer works on the principle of mixing by means of central worm shaft, which is partly placed in the external tube. Mixing time is 15 min. For discharge of finished feed mixture, in the lower part of the mixer there is an outlet with manual sliding gate with position locking.

The finished feed mixtures are discharged from the mixer through the manual sliding gate and an inclined screw conveyor. The screw conveyor can discharge the feed mix into a transport container or in big-bags. Furthermore, the screw conveyor is equipped with the second discharge with manual sliding gate and bagging spout for possible bagging of the feed mix.

| MVKS-V 500 | 0,5 t / h |

| MVKS-V 1000 | 1,0 t / h |

| MVKS-V 1500 | 1,5 t / h |

| MVKS-V 2000 | 2,0 t / h |

Small feed mill MVKS-T

Small feed mill MVKS-T is a plant consisting of a self-suction hammer mill and a vertical weighing mixer. The self-suction hammer mill suctions cereals to be ground through a mixing device into a milling chamber, where the raw material is crushed by hammers, and calibrated through a screen to required granules. The screens can be easily replaced in off condition. The screen mesh size is selected depending on the kind of animals the feed is to be produced for. The hammer mill further transports the crushed raw material through an outlet pipe to the vertical mixer. The mixer works on the principle of mixing by means of central worm shaft, which is partly placed in the external tube. Mixing time is 15 min.

The mixer is equipped with an aspiration bag with bottom cleaning to remove excess air from the mill. In the lower part of the mixer there is a hopper for manually poured components. For discharge of finished feed mixture, in the lower part of the mixer there is an outlet with manual sliding gate with position locking.

The complete mixer is installed on a frame with strain gauges, which ensure gradual weighing of individual components, which are crushed and manually dosed through the lower hopper of the mixer.

The finished feed mixtures are discharged from the mixer through the manual sliding gate and an inclined screw conveyor. The screw conveyor can discharge the feed mix into a transport container or in big-bags.

| MVKS-T 500 | 0,5 t / h |

| MVKS-T 1000 | 1,0 t / h |

| MVKS-T 1500 | 1,5 t / h |

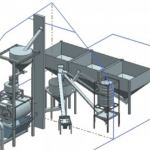

Feed production line PP

The feed production line is designed as a system of three square bunkers for cereals, which are regularly supplied by front-end loader from the floor storage. The capacity is 3 x 10m3. The raw materials are weighed from these bunkers into the strain-gauge balance with capacity of 500 kg of feed mixture. The weighed charge is then transported into the milling line, which consists of the vertical hammer mill VM 15 with automatic dosing of ground stock in the milling chamber. Over the hammer mill there is a magnetic separator, by means of which ferromagnetic impurities are removed from the material.

Premixes and feed additions are stored in textile big-bags, which are suspended in special frames with the screw conveyor, which discharges into the strain-gauge balance. These materials are delivered outside the hammer mill directly into the mixer.

The mixing itself takes place so that the vertical hammer mill discharges the material into the horizontal mixer, and the raw materials, which need not be crushed, are filled into the mixer outside the milling line. Cylindrical turning-over mixer PM 130 – 500 is designed for mixing with working accuracy 1 : 100 000 and mixing time 8 minutes. The mixed mixture is discharged from the mixer by its turning over into the bunker under the mixer. From the bunker the mixed mixture is transported by the conveyor into the storage bin before granulation or in bulk state into the feed transport container. The mixer has a manual loading of components, and enables spray of vegetable oil into the mixed feed mixture.

Trough mixer with hammer mill

Trough Mixer produced by our company is a machine designed for mixing dry loose mixtures and similar materials. Use for other materials has to be tested first. The Machine is designed for integration into technological units for mixing dry loose mixtures consisting of storage equipment for materials intended for mixing (silos), transport routes, and connected technological equipment for processing loose mixtures. When deciding on using the Machine with particular technological equipment and in particular premises, the issues of usage of the Machine and solution of transport routes according to the given specific requirements must be consulted with the Machine Supplier. The mixer is driven by a slip-on worm gear with electric motor on a worm shaft.

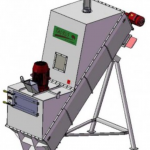

Feeding device

Feeding Device produced by our company is a machine designed for gradual feeding of loose materials (products) from containers and silos in feed mills and at grain silos and similarly deposited loose materials (products) by constant speed (chosen according to the customer’s requirements). The inlet is positioned over the feeder rotor. The material is gradually transferred to the bottom outlet by feeder rotor rotation. An electric worm-gear serves as a drive unit.

Want to know more? Download product leaflet here or send us an email.