Cool Plasma Gasification

AdaptiveARC’s patented COOL PLASMA™ Gasification Technology utilizes a combination of plasma fields, pulsed-energy technology, and UV detoxification to produce the cleanest, most cost-effective, and energy-efficient solution available.

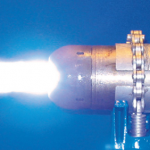

The COOL PLASMA Gasification Technology converts waste, or other carbonaceous feedstock, into operationally viable outputs using plasma field dynamics. Waste flows through a plasma arc (see Figure 1) generated by pressurizing a gas (a combination of diesel, air and electricity) and passing it through an electrical field in an oxygen-deprived chamber. This produces a high-heat environment (800-1000°C), which instantaneously breaks down the waste feedstock into its molecular components. Super heating without oxygen is not incineration and does not generate the problematic exhaust emissions produced by burning waste. Instead, the innovative COOL PLASMA Gasification technology creates a clean fuel called syngas (synthesis gas) that can be used to generate a wide range of valuable outputs including electricity, liquid fuels, and specialized chemicals. The waste feedstock material introduced into this process is detoxified and its weight reduced at a ratio of 20:1. The only solid byproducts are inert materials: dry fly ash (which is commonly used as a construction aggregate), glass, and metals.

System Overview

The Clean Energy 25 (ce25) plasma arc processor utilizes the COOL PLASMA Gasification technology to eliminate up to 25 metric tons of waste per day (TPD); the system can also be turned down to process reduced ratios or can be run intermittently as needed. The ce25 can operate 7 days per week, 365 days per year. It is energy self-sustaining and generates excess electric power that can be used for other external needs or can be fed back into the grid. The ce25 can be used for a host of operational applications such as municipal solid waste (MSW), toxic waste, and bio-hazardous waste.

The system, unlike other gasifier or pyrolysis systems, also accepts waste fuels with up to 55% moisture content and has the ability to process multiple fuel types without having to be reconfigured. The ce25 is designed to produce over 500kW of net continuous power output when processing 25tpd. A unique energy balancing feature corrects for the incidental energy fluctuations typical in waste streams when used as a fuel source. If there is a fluctuation in the waste fuel syngas production, the generator-set (gen-set – engine-generator combined into one machine) will automatically start drawing in more or less diesel to compensate for the adjusted syngas values of the waste fuel thus providing a continuous energy output level. The proprietary gen-set modifications of the ce25 system are designed to adjust for these shifts with no degradation to the system’s capabilities.

Plasma Arc Waste Destruction System (PAWDS)

The commercial success of PAWDS was confirmed by the purchase of a commercial system by Carnival in 2002 and the decision by the US Navy to contract Northrop Grumman Newport News in 2008 to procure a PAWDS unit for the USS Gerald R. Ford. The PAWDS for the Ford carrier was delivered in late 2011. The USS John F. Kennedy, was received in 2012.

Description of the technology

The Plasma Arc Waste Destruction System (PAWDS) is a versatile, compact and easy to operate waste-to-energy system that can be started and stopped within a few minutes, making the system extremely safe and flexible. Originally developed for shipboard waste destruction, its extremely compact and cost-effective design makes it an ideal solution for land-based applications. PAWDS uses the intense energy of a plasma plume to efficiently gasify waste material. The resulting syngas can then be immediately combusted. It is important to note that plasma runs off of electricity, and as such, will not require a generator and fossil fuels to operate.

The PAWDS is to be composed of the following main sections:

- Feed Preparation System – Sorting equipment – Milling System

- Plasma–Fired Eductor

- Combustion chamber

- Off-gas treatment system

The PAWDS works as follows: Unsorted Mixed Solid Waste (MSW) is fed to the shredder, where its size is reduced. The shredded waste is then conveyed to a hopper-mixer where it is then pneumatically fed to a mill which transforms it into a lint-like substance. The milled waste is then introduced into the plasma fired educator (gasifier) where it is converted to a syngas. The syngas then fed to the combustion chamber, where air is injected to ensure the full combustion of the syngas. The resulting combustion gas is then cooled dramatically to under 100oC in order to prevent the formation of dioxins and furans. The gas is then passed through a Venturi scrubber to remove particulate matter. The whole system is kept under negative pressure by an induced draft (ID) fan, which simply exhausts the clean combustion gas to the atmosphere.

Ready Commercial offer

Strebl Energy and PyroGenesis is pleased to offer a Plasma Arc Waste Destruction System in order to meet your needs regarding clean waste management. The PAWDS showcased in the proposal (ask for a copy), will manage the 5 MT per day of waste with energy recovery equivalent to 800kW (687.9Mcal/h) suitable for high-rise building and building complex in Singapore. We have ellaborated preliminary study for potential client in Singapore with attractive payback and long term profitability.

Plasma Atomization Process and Technology

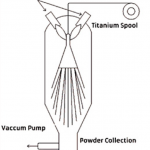

Developed by PyroGenesis, the Plasma Atomization Process uses argon plasma torches to melt and atomize into fine droplets titanium and other metals. The Plasma Atomization Process has the distinction of producing highly flowable and very pure spherical metallic powders using wire as feedstock. Because of the inert argon atmosphere, high powder purity can be achieved. The high temperature, high kinetic energy plasma allows for the production of a highly spherical powder. Since a wire spool is used as feed material, a high level of traceability is achieved, allowing for the use of the powders for high-end applications such as biomedical implants, or for the aerospace sector. In the Plasma Atomization Process (Figure 3), a pre-qualified wire is continuously fed through the apex of three non-transferred arc argon plasma torch jets. Simply put, the wire begins to melt from the >10,000°C plasma and become atomized into fine droplets. For this application, PyroGenesis’ RPT torches are used. These torches use tungsten electrodes, ensuring minimum erosion and contamination of the powder.

- Plasma Atomization Process

- Three Argon Plasma Torch Jets Converging on Wire

- Sample powders produced by plasma atomization

Plasma Atomization Process

Droplets shear off in a superheated state, completely consuming the wire (Figure 2). The droplets disperse, and then fall down a tall water-jacketed, argon-filled tower. The droplets spend enough time in freefall to physically transform into their most natural state dictated by surface tension: a perfect sphere. The spheres are collected semi-continuously under an argon blanket, and can then be sieved to different sizes, depending on customer requirements. A high degree of sphericity and a narrow particle size distribution is desirable in advanced material fabrication processes involving powders. Examples of powders are shown in Figure 1

Benefits:

- Site development, design and concept

- Highly Spherical

- Few Satellites or Internal Voids

- Highly Flowable Compared To Angular and Other Spherical Powders

- Low Oxygen Content and No Contaminants

- Tailored Size Distribution

- Highly Traceability

Plasma Arc Waste Destruction System (PAWDS)

The commercial success of PAWDS was confirmed by the purchase of a commercial system by Carnival in 2002 and the decision by the US Navy to contract Northrop Grumman Newport News in 2008 to procure a PAWDS unit for the USS Gerald R. Ford. The PAWDS for the Ford carrier was delivered in late 2011. The USS John F. Kennedy, was received in 2012.

Description of the technology

The Plasma Arc Waste Destruction System (PAWDS) is a versatile, compact and easy to operate waste-to-energy system that can be started and stopped within a few minutes, making the system extremely safe and flexible. Originally developed for shipboard waste destruction, its extremely compact and cost-effective design makes it an ideal solution for land-based applications. PAWDS uses the intense energy of a plasma plume to efficiently gasify waste material. The resulting syngas can then be immediately combusted. It is important to note that plasma runs off of electricity, and as such, will not require a generator and fossil fuels to operate.

The PAWDS is to be composed of the following main sections:

- Feed Preparation System – Sorting equipment – Milling System

- Plasma–Fired Eductor

- Combustion chamber

- Off-gas treatment system

The PAWDS works as follows: Unsorted Mixed Solid Waste (MSW) is fed to the shredder, where its size is reduced. The shredded waste is then conveyed to a hopper-mixer where it is then pneumatically fed to a mill which transforms it into a lint-like substance.

The milled waste is then introduced into

the plasma fired educator (gasifier) where it is converted to a syngas. The syngas then fed to the combustion chamber, where air is injected to ensure the full combustion of the syngas. The resulting combustion gas is then cooled dramatically to under 100oC in order to prevent the formation of dioxins and furans. The gas is then passed through a Venturi scrubber to rem ove particulate matter. The whole system is kept under negative pressure by an induced draft (ID) fan, which simply exhausts the clean combustion gas to the atmosphere

Ready Commercial offer

Strebl Energy and PyroGenesis is pleased to offer a Plasma Arc Waste Destruction System in order to meet your needs regarding clean waste management. The PAWDS showcased in the proposal (ask for a copy), will manage the 5 MT per day of waste with energy recovery equivalent to 800kW (687.9Mcal/h) suitable for high-rise building and building complex in Singapore. We have ellaborated preliminary study for potential client in Singapore with attractive payback and long term profitability.

Plasma Resource Recovery System

Responsible waste management is a growing concern worldwide.

Our technologies offer practical and effective solutions, adaptable to a wide range of wastes, using approaches that are safe, easy to use, and flexible. Our vision of being innovators in the waste-to-energy arena became a reality in 2010 when PyroGenesis Canada delivered a transportable, turnkey 10.5 tonnes per day PRRS located on a U.S. Air Force base in Florida. No other company in the world can boast of having a plasma gasification system accepted in a commercial setting by such a discerning customer, placing PyroGenesis at the forefront of this industry.

Unique and ahead of its time, the PRRS has the ability to be transportable and operate in all types of enviro ments such as municipalities, hospitals, airports, industries, forward operating bases, or even in emergency situations (ex. petroleum, oil or chemicals spills). With the patented technology for gasification and vitrification, the PRRS is environmentally sound and a net energy producer. The system converts unsorted waste into syngas, while the inorganic portion is transformed into a vitrified, reusable slag resembling glass, thus immobilizing potentially toxic components contained in hazardous wastes.

The energy produced can be recovered by various means depending on your needs and your technological goals!

Significantly smaller footprint as compared to conventional incineration technologies. Impressive ROI for both small and large capacities. Production of energy and useful construction materials, with no secondary waste to treat

Clean resource recovery technology. Electricity from waste without dioxin and furan emissions. Significant, positive impact on greenhouse gas reduction.

Minimal sorting required Fully automated system Onsite or remote operation / troubleshooting Operators do not require a high level of schooling.

Steam Plasma Arc

SPARC

-

The power of STEAM PLASMA HYDROLYSIS

-

Compact, efficient destruction

-

Easy to operate

-

Highly cost effective

-

Mobile

SPARC is a highly efficient, patented process for the destruction of chemical wastes, such as refrigerants, ozone depleting substances, and other gaseous wastes. Operating with a steam plasma plume temperature of more than 5000°C at its hottest point, the waste is fed continuously to the two-zone plasma reactor. With a reactor temperature of over 1300°C, the steam plasma hydrolysis reaction quickly and efficiently breaks down the waste into carbon dioxide (CO2) and water (H2O). The gas stream is then rapidly quenched to prevent any formation of dioxins and furans. Acid gases generated by the process are readily scrubbed out of the stream and neutralized, resulting in an offgas that easily meets environmental regulations.

LOW CAPITAL COST – This compact, purpose-built waste destruction system is designed uniquely for the specific waste streams to be treated, as opposed to a one-size fits all conventional incineration system.

LOW OPERATING COST – Typical hazardous waste incineration systems are over designed, requiring massive amounts of air to complete the combustion reaction. In hydrolysis, lower air requirements means smaller scrubbing and ventila-tion, thus reducing consumable and electrical consumption in the offgas abatement process. In addition, incinerators typically need to be operated at well under their normal operating capacities to be able to scrub acid gases from chemical destruction, rendering large incineration systems highly inefficient.

MOBILE/IN SITU DESTRUCTION – With its small footprint and ease-of-operation, SPARC can easily be deployed as a mobile system or be bolted on to an existing industrial operation. This feature allows the operator to process its waste stream at the point of generation, resulting in a much lower operating cost as compared to 3rd party waste destruction service providers.

PROVEN TECHNOLOGY PLATFORM – SPARC is based on two proven technology platforms, namely PyroGenesis’ Air Plasma Torch (APT) and its patented Plasma Arc Waste Destruction System (PAWDS). Both technologies have met the stringent requirements of the US Navy and is currently being installed on an aircraft carrier.