Plasma Arc Waste Destruction System for on-site waste management for commercial buildings turning waste in to a resource – energy recovery for off-grid electricity.

Existing Facilities / Infrastructure

Since 1999, our partner company PyroGenesis Canada Inc. has been working closely with the United States Navy with the objective of developing a novel technology for the compact, safe and efficient destruction of shipboard wastes. The result of this multi-year collaboration has been the patented PAWDS.

The commercial success of PAWDS was confirmed by the purchase of a commercial system by Carnival in 2002 and the decision by the US Navy to contract Northrop Grumman Newport News (now Huntington Ingalls, Newport News Shipbuilding division) in 2008 to procure a PAWDS unit for the USS Gerald R. Ford – CVN 78 supercarrier which is the first ship of three, in the CVN 21 Aircraft Carrier Series.

The PAWDS for the Ford carrier was delivered in late 2011, and is currently being installed onboard the ship. The follow-on order for the second Ford-class ship, the USS John F. Kennedy, was received in 2012 and construction is currently underway at PCI’s facility with an estimated completion date of Q2-2014.

The Plasma Arc Waste Destruction System (PAWDS) is a versatile, compact and easy to operate waste-to-energy system that can be started and stopped within a few minutes, making the system extremely safe and flexible.

The Navy’s decision to install a PAWDS to treat 5 tons per day of waste on an aircraft carrier involved many years of development and “Go-No Go” evaluations. The technology had to be able to be fully automated, easy to use, extremely compact, able to treat a wide variety of combustible waste and be able to start-up and shut-down in just a few minutes. The decision to install it on the Ford aircraft carrier was the result of a successful 60 day round the clock operation of the PAWDS unit by US Navy Sailors to evaluate its reliability, mean time between failures, mean time between repairs as well as its overall ease of use. The positive results from these tests resulted in the US Navy’s decision to move forward with this state of the art technology which can process 5 tons per day of mixed waste, including the types of waste being addressed by this solicitation.

Description of Test-bed

Strebl Energy understands that the amount of waste from commercial facilities to be disposed of is usually quite significant. Additional time, effort, and energy usage for transportation needed to collect the waste hence makes it an inefficient process.

The PAWDS

Green waste management for high rise or large buildings in CleanTech Park is certified to the highest level of international environmental standards and certifications. The low emission cleantech system will provide to the project a high environmental standard in waste management.

The energy produced by this system may be recovered in hot water to a thermo pump systems (heating and acclimatization) or a boiler steam, depending of what king of systems can be integrated in the project. We believe that the energy produced with the PAWDS will recovered the initial power needed plus additive annual revenue.

Strebl Energy Pte Ltd, together with PyroGenesis Canada Inc., is pleased to offer a Plasma Arc Waste Destruction System (PAWDS) test bed to be installed in high rise or large building for the purpose of clean waste management. The PAWDS showcased in this proposal will manage the 5 MT per day of waste with energy recovery equivalent to 800kW (687.9Mcal/h)

We also included in this technical proposal Equipment list, OPEX, Foot print, Infrastructure needed, and a process flow.

Test bed of PAWDS on high rise buildings

The PAWDS is originally developed for shipboard waste destruction, and the extremely compact and cost-effective design makes it an ideal solution for land-based applications. PAWDS uses the intense energy of a plasma plume to efficiently gasify waste material. The resulting syngas can then be immediately combusted. It is important to note that plasma runs off of electricity, and as such, will not require a generator and fossil fuels to operate.

Test-bed Objective

Full scale installation in Singapore.

Methodology

DESCRIPTION OF THE TECHNOLOGY

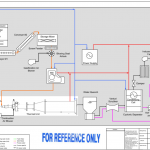

The PAWDS is to be composed of the following main sections:

- Feed Preparation System – Sorting equipment – Milling System;

- Plasma–Fired Eductor;

- Combustion chamber;

- Off-gas treatment system

The PAWDS works as follows: Unsorted Mixed Solid Waste (MSW) is fed to the shredder, where its size is reduced. The shredded waste is then conveyed to a hopper-mixer where it is then pneumatically fed to a mill which transforms it into a lint-like substance. The milled waste is then introduced into the plasma fired educator (gasifier) where it is converted to a syngas. The syngas then fed to the combustion chamber, where air is injected to ensure the full combustion of the syngas. The resulting combustion gas is then cooled dramatically to under 100oC in order to prevent the formation of dioxins and furans. The gas is then passed through a Venturi scrubber to remove particulate matter. The whole system is kept under negative pressure by an induced draft (ID) fan, which simply exhausts the clean combustion gas to the atmosphere. A cooling fluid circulates in the plasma torch, around the combustion chamber, through the mill, and inside the condensing coil to remove heat from the process. This heat transfer to the cooling water represents 800 kW of energy.

- PAWDS for USS Gerald R. Ford Supercarrier

- Simplified PAWDS-ORC Process Flow Sheet

Want to know more? Contact us!