E-Rational

E-Rational, a division of BEP Europe, is the first Belgian enterprise to provide the world with a compact solution for converting waste heat into green, sustainable energy. BEP Europe’s ENERGY mission is to provide sustainable energy solutions based on common sense: No Heat To Waste! E-RATIONAL stands for a rational, logical approach of sustainable energy production. With a subtle hint of irrationality in our brand name, we want people to start thinking about current irrational energy approaches and use again their common sense. The letter “E” refers to Electricity, Energy, Economy, Ecology, Equilibrium, Evolution, Earth.

As a company, BEP Europe has 30 years of experience as equipment manufacturer for automation projects (such as Tire and Wheel assembling), end of line test equipment for automotive industry (such as Roll/Brake test systems) and industrial set-ups for reliability testing of vehicles (laboratory tests such as dynamometers). The experience for development of new products and the close cooperation with local universities formed a good background to develop the E-Rational ORC machine.

The synergy between state-of-the-art technology and traditional, standard components makes the E-RATIONAL ORC machines to what they are today: user-friendly, robust and economically viable installations. Consistent reasoning combined with proven facts has led to our E-rational product range.

ORC

A modular and scalable design makes almost any kind of waste heat suitable for cheap green energy production. A variety of heat sources – e.g. waste heat from industrial processes, residual heat from CHP units, geothermal heat or excess heat from district heating nets – are applicable to fuel the Organic Rankine Cycle (ORC). E-RATIONAL offers a CE-compliant machine, with one of the lowest power production costs in industry.

The main focus, during design phase of the machine, has been a maximized uptime and efficiency at a minimized operational and maintenance cost, resulting in a skid-mounted modular machine with plug-and-play connections for convenient installation.

E-RATIONAL has a product line for ORC machines to recover heat up to maximum 4 MWth, for heat streams with temperatures of minimum 80°C to maximum 150°C, with an electricity production ranging between 55 and 500kWe. According to the specifications of the customer, the most suitable solution will be offered. The heart of the machine is the E-RATIONAL Expander, a very robust single screw expander, developed internally by BEP EUROPE’s Engineering Department.

Cycle of the machine

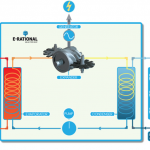

The working principle of the machine is represented in the figure below. The cycle is started at the pump, which is pumping the refrigerant – the fluid of the internal circuit of the machine – to the evaporator. At the evaporator, the available waste heat is used to evaporate the fluid. The saturated gas at the outlet of the evaporator is send to the expander. The expansion of the gas is delivering the work to drive the generator, resulting in the production of electricity. Supersaturated low pressure gas is leaving the expander to be condensed in the condenser. The fluid leaving the condenser will be pumped up to restart the cycle.

Advantages of E-RATIONAL ORC system

- Reuse of waste heat: elimination of the costs for “heat dumping”

- Zero emissions: environment friendly machines

- Reduction on the electricity bill: electricity from (free) waste- or residual heat

- No fuel consumption

- Production costs for electricity are competitive: the technology is profitable even at lower electricity prices

- Electricity produced from waste heat is basically free: Additional subsidy may apply depending on the application and the local policy

The process is therefore a distinct power supplier offering immediate significant financial and ecological benefits.

Standard Scope of Delivery

Specifications of the machine

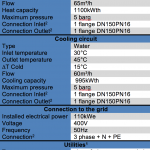

The specifications of the machine are summarized in the Table in the gallery. It is the customer’s responsibility to make sure utilities1 are provided and accessible on-site. The connections on-site need to fit the connections2 specified in the table. Note that the minimum flow3 of compressed air will only be consumed at start-up and shut down of the machine, during approximately 2.5 seconds.

- Design parameters of the ORC

- ORC machine indoor installation

- ORC machine indoor installation

- Schematic representation of the ORC machine

Based on the described parameters in Table in the gallery, BEP Europe proposes as to be the best solution an ORC machine type ORC HT-111/110kWe.

Housing

The price includes housing of the machine suitable for indoor installation. The housing is soundproof. BEP can offer housing suitable for outdoor installation on request.

The ORC machine is CE compliant according to following directives:

- Machine directive: 2006/42/EG

- EMC directive: 2004/108 EG

- Low voltage directive: 2006/95/EG

- Pressure equipment directive: 97/23/EG

- IP rating: IP32

BEP Europe guarantees the safety of its products. Approval for the complete project and integration on-site is the responsibility of the customer.

Control unit

The machine is provided with a Siemens PLC and control panel on the electrical cabinet.

Documentation

Documentation listed below will be available in English for the customer at delivery time of the machine.

- Operations and maintenance manual

- Electrical diagram

- Process and instrument diagram

- Declaration of conformity

Warranty

The standard scope of delivery includes a warranty period of one year, starting at the time the machine is put into service or at the latest 1 month after delivery on site, whatever comes first.

The warranty is valid in case of good operating practice. The machine was designed to be operated in the conditions described in Table. If damage occurs due to deviation of the operational conditions, warranty is no longer valid.

By no means the warranty covers the normal wear and tear, nor parts such as lamps, fuses, etc. Break down repairs due to improper use of the machine are not covered by the full service contract.

Performance guarantees

Performance guarantees are strictly defined on the specifications in the Table. The machine performance depends on the inlet and outlet temperatures of the hot and cooling circuit as well as the total amount of heat delivered to the machine. The hot circuit and the cooling circuit including the cooling units are no part of the scope of supply. It is the customer’s responsibility to install a suitable cooling with enough capacity as to reach this cooling water temperature. The guaranteed percentage of expected efficiency has to be interpreted as a net efficiency (including consumption of the electrical cabinet and the ORC pump). The expected power production will vary between summer and winter time.

If the above is understood, an efficiency of 8.5% with an offset of ± 0.5% can be guaranteed in case the operational conditions mentioned in Table 1 are respected within a margin of ±5% on daily basis.

Mandatory equipment

The customer should provide a shut-off valve at the hot circuit. This will prohibit the supply of heat in case the machine is not in operation. It is strictly forbidden to supply heat in case the cooling circuit of the machine is not activated.

For information: the machine includes a digital output to open this valve at startup of the machine.

Recommended equipment

It is recommended to install a flow measurement device at the hot or cooling circuit of the machine. The flow measurement is no part of the scope of supply. Interfaces to use and display the 4-20mA signal from the flow measurement, in case installed by the customer, are available on the machine. Electric cabling has to be done by the customer. BEP Europe can be consulted to provide a flow measurement to be installed at the hot or cooling water circuit.

Not included: installation on site

Connecting of hot and cooling circuit

The flanges for connection of the hot and cooling water piping are specified in Table. The piping on site to the machine is not included in the scope of supply.

Connection to the grid

BEP Europe is not responsible to acquire permits for connection to the grid. The electrical cabling for connection to the grid is not included in the scope of delivery. Interfaces for connection to the grid and signal transfer are provided on the machine. Grid connection is specified in Table.

Pre-engineering Study

At the start of the project, a qualified BEP Europe Engineer will perform a site visit to survey local installation conditions. Activities of this option include the study of following aspects:

- Inspection of the available space to install the machine and electrical cabinet

- Stability and ambient conditions of the machine

- Accessibility and piping requirements for the hot and cold circuits

- Connection to the grid

- Availability of the utilities

The result of this study will be a report to inform the customer with the necessary work to be done for installation of the machine, together with the specs for parts (pumps, coolers, etc.) to be installed outside of the scope of BEP Europe. The price includes 1 day of site visit (incl. travel costs) and 4 days of engineering study.

The pre-engineering study is ordered before the actual machine order to determine the configuration and the resulting specifications of the machine. If ordered, the cost of the pre-engineering study can be deducted, as a discount, on the final order of the machine.

On-Site Support

This option includes supervision during installation, commissioning and training of the ORC operators. BEP Europe’s qualified engineers can assure on-site assistance and management during these activities. The activities of the on-site support are further specified.

- Transport and installation

- Arrangement of the machine at the foreseen location

- Assistance for connection of the piping of the hot and cold water circuits

- Assistance for grid connection

- Assistance for connection of the compressed air

- Commissioning

- First start-up of the machine

- On-site acceptance of the machine

- Training

- Explanation on good operations of the machine

- Operating the control panel

- Guidance on error and warning handling

- Maintenance program for operators

BEP Europe will provide these activities once all preparations for reception and installation are done. The activities will occur in a time frame of 5 days, excluding contingent developments outside of BEP’s responsibility. Additional time necessary to finish the activities, in case of delay outside of BEP’s responsibility, will be charged to the customer. Travel time, travel costs and expenses for BEP personnel are included in the price.

Maintenance Schedule

BEP Europe specifies a dedicated daily follow up on the conditions of the machine during the first month of installation of the machine on-site by the operator. After the first 24 hours and 168 hours (first week) of operation, there should be an inspection at all flanges for leakages and tightening of the bolts. An extra preventive cleaning of the magnetic filter should be executed after the first 168 hours of operation. The machine should be stopped to clean the filter.

The E-Rational ORC units are built-up with mainly standard components requiring minimal and simplified maintenance. First line maintenance includes the preventive maintenance to be executed by on-site maintenance. On-site maintenance should inform the ORC operators by filling in an inspection report. Second line maintenance includes the follow up of the machine. At last, BEP Europe prescribes a two yearly overhaul of the machine to be executed by BEP assigned personnel. The expected time the machine will be out of service during the overhaul is in a range of 1 to 3 days, depending on the conditions of the machine.

Want to know more? Contact us!